A professional slicer is equipped with a blade that can work at high speed, all the while maintaining very high precision. In fact, most of those who use professional slicers are butchers, delicatessen workers, rotisseries, restaurants, that need to slice a large amount of food items every day.

However, each of them has different needs. To respond to them all, we at Manconi have come up with three different lines of slicers:

- Kolossal – Our top of range, ensuring easy handling, excellent yield, and resistance over time.

- Kolossal Dual – Born of the restyling of some Kolossal models, characterized by modern design and rounded shapes. The “dual” part of the name refers to the possibility to choose the type of sharpener (either separate or built into the machine) and of transmission (belt or gears).

- Smarty – The new generation of slicers for restaurants: resistant, safe, small, and with a customizable design.

Professional slicer must-haves

The main features of a professional slicer are efficiency and resistance to cut large amounts of products on a daily basis with m maximum precision, without jamming incidents, and making the operator’s movements easier.

For this to be possible, a professional machine must absolutely have a few specific components:

- A spacious and sliding surface that ensures great support for products, including voluminous ones

- The possibility to choose the type of slicer with separate sharpener, which makes cleaning easier

- Removable elements, to make it easier to clean

- Reduced loading height, to make it less tiresome for the operator

- Resistance to mold, bacteria, corrosion, and wear

- Compliance with European standards, directives, and regulations regarding hygiene and safety

The perfect professional slicer for you: our suggested models

The Smarty line includes some of the most popular models of professional slicer, versatile and small at once.

We particularly advise 300 IX, 350 VX BV, and 330 IK.

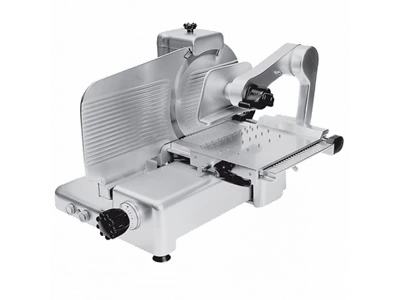

300 IX

Cold cuts, cheeses, and pre-cooked foods can be perfectly sliced, without waste, with the 300 IX slicer, also available with 250 or 350-mm blade.

This is a compact model that can be installed in small places. Available in red or black. Some of its technical features:

- Belt transmission

- Built-in sharpener

- Reduced load height

- Tilting product tray and grooved presser for effective grip

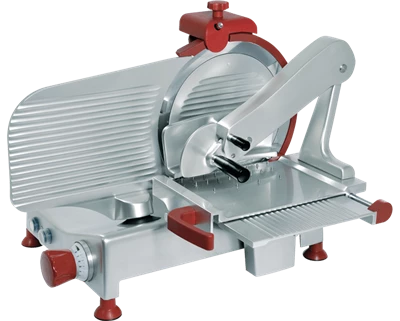

300 VX BV

The professional slicer that is perfect for prosciutto, cold cuts in general, roast meats. Also available with 350 and 370-mm blade, this machine is equipped with a vertical pantograph arm with fixed aluminum presser and with:

- Belt transmission

- Built-in sharpener

- Small size

- Removable product tray for better cleaning

Also available in a colored version, with red or black knobs.

330 IK

Suitable for the slicing of cold cuts, sausages etc., bread and vegetables, the 330 IK offers high-precision cuts and reduced loading height, to reduce operator fatigue.

This slicer is equipped with:

- Gear transmission

- Built-in sharpener

- Blade diameter: 330 mm

- Removable sharpener, blade cover, slice holder and grooved presser, for better cleaning

The machine can be accessorized with different types of tray, such as:

- Tray with tilting product presser, transparent and removable

- Tray with tilting product presser, made of aluminum and removable

- Tray with self-locking arm, transparent and removable product presser, and sliding tray

All of Manconi’s services

When you purchase a professional slicer, you might need help with its installation or you can simply decide to provide your personnel with training on the functions of the new machine.

All you need to do is contact us: we’ll forward your request to one of our one hundred qualified technicians all over Italy, who will be ready to answer your questions.

What if you want to personalize your slicer? When placing your order, you can choose to have some parts or the entire slicer painted with non-toxic colors, suitable for contact with food products.

Which slicer is best for your needs?

Contact us free of charge and discover the entire Manconi range

Leave your comment