Improper use of the slicer results in uneven slices that will make customers dissatisfied, thereby damaging the image of the entire business. Not to mention that, if not used to its best advantage, a professional slicer also results in more product waste.

Plus, an optimally used slicer will ensure greater resistance and durability over time.

How to use a professional slicer: a few simple rules

The correct use of a professional slicer starts by choosing the slicer itself. Choosing the right slicer based on the product to be sliced is fundamental for obtaining quality cuts.

In general, using a professional slicer correctly will involve a few simple tricks:

- First and foremost, read the instruction manual, especially if this is your first use

- Adjust the thickness of the slice using the knob provided and connect the plug to the power supply

- Place the product to be sliced on the sliding board

- Press the power button and slide the product towards the blade

Additionally, be sure to check that the blade is always sharp and, if necessary, sharpen it. (link to 5 PED article).

Using a professional slicer at its best: periodic maintenance

Necessary periodic maintenance must be performed for a professional slicer to deliver even better performance.

What does this involve?

Thorough and deep cleaning is the main way to keeping your professional slicer in the best condition. Correctly using a slicer also involves knowing how to clean it.

First, you need to disconnect the machine from the mains, disassemble all its removable parts and wash them thoroughly.

Then you can focus on the machine's body, from which you need to remove all remaining food residues using paper towels. Now, wash the body of the machine with soap and water or other specific detergents and an anti-scratch sponge.

Finally, you can reassemble all the parts and check that the professional slicer is working correctly.

When cleaning, always remember to be very careful with the blade to avoid dangerous accidental cuts.

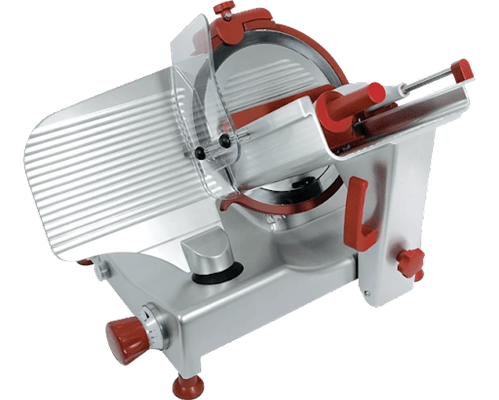

Manconi professional slicers: easy to use and maintain

Wondering where to start in order to use a professional slicer at its best? Choosing a Manconi professional slicer, one of the main meat slicer manufacturers, is a real winning move. These tools are highly accurate, hygienic and safe, designed to last over time and make the operator's job easier.

All models are electric and have a low loading height, and several components can be disassembled to facilitate cleaning and maintenance.

Each model of the three Manconi lines offers the best in quality of materials, modern technology and safety standards. All Manconi professional slicers are designed and manufactured in compliance with current European regulations.

- Smarty – The Manconi line is the latest development and includes numerous models suitable for the catering sector. It is available in red and black.

- Kolossal – the right balance between tradition and innovation; this is the top of Manconi's range, with professional slicers that benefit from Manconi's tradition and experience while keeping an eye on the future.

- Kolossal Dual – while maintaining the quality standards of the Kolossal models, it offers slicers with a more modern design and with numerous options available.

Do you need a professional slicer that makes your job easier? Choose Manconi:

Leave your comment