Commercial slicer: Manconi high quality proposals to buy the best

Manconi offers a wide choice of commercial slicers suitable for many different needs. Since the high quality of the machines, you will easily find the best slicer according to your professional activity. In the following guide we will list a series of advices to help you find the best models of commercial slicer.

- Manconi’s commercial slicers

- Which product do you have to cut?

- Vertical or gravity slicer?

- Electrical operation

- Choose a model that can be disassembled

- Compliance with the current European regulation

- Customize your commercial slicer

Manconi's commercial slicers proposals

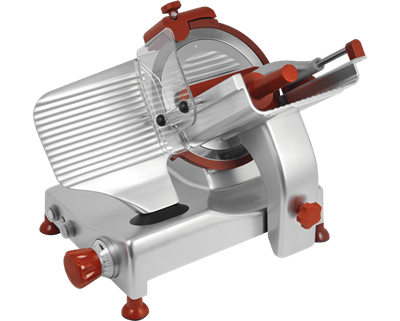

250 IK is a gravity slicer perfect for cutting cured meats, cheeses and pre-cooked meats. Its small size makes it a flexible and versatile product that can be placed even in tight spaces. The reduced loading height reduces operator fatigue and despite its size is an accurate and reliable slicer even for everyday use.

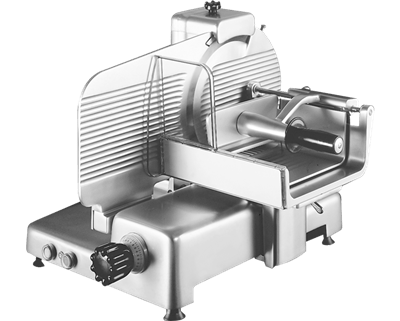

Perfect for the safe and precise cutting of all types of meat. The wide base of support allows the regular cutting of large sized pieces. The materials of which it is made resistant to impact and corrosion, ensuring maximum hygiene. It can be completely disassembled for easy, quick maintenance and ensuring longevity.

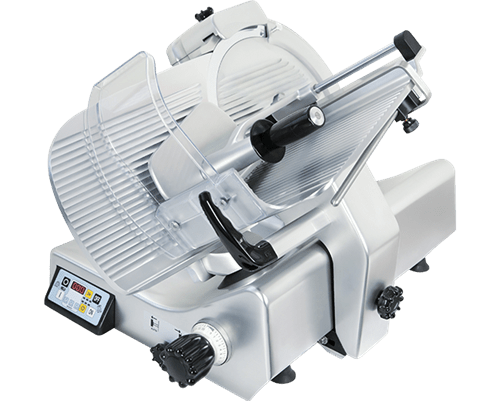

This gravity commercial slicer is suitable for cutting all types of meats, cheeses and pre-cooked meats. The tilted plate and the reduced loading height facilitates the use by the operator. The great cutting capacity make it an indispensable tool for the professional, to reduce waste and optimize working time.

Are you interested in buying a high performing commercial slicer?

Contact us for more information

1.Which products do you have to cut?

Depending on your business, you have to slice one or more specific kind of food. If butcheries only need to cut fresh meat, other activities such as Deli stores, Food stores or Ho.Re.Ca. professionals need to cut a wider range of products. The best producers of commercial slicers offer machines specifically designed to cut one or more products, from meat (also frozen meat), to cheese, cold cuts, roasts, fish, bread, and even vegetables. Identifying the products to cut is therefore the first step in the best choice of your commercial slicer.

2.Vertical or gravity slicer?

All the models of commercial slicer are included in one out of two big families:

Vertical slicers: vertical slicers are equipped with a blade that is perfectly perpendicular to the plate, meaning a reduced size of the machine and the need to keep manually the product in contact with the blade during the cut.

A vertical meat slicer by Manconi

Gravity slicers: in the models of gravity commercial slicer, on the contrary, the blade is slightly sloping, letting the product slide towards the blade without manual intervention; they are more comfortable to use, but they also occupy more space than vertical slicers.

A gravity meat slicer by Manconi

Depending on the spaces and the needs of your activity, you can choose either a vertical or a gravity slicer.

3.Electrical operation

For professional businesses, it would be better to avoid manual slicers – also known as flywheel slicers – as they are less efficient in cutting the product. We recommend choosing an electrical professional slicer that guarantees a steady, fast and comfortable movement of the blade, optimizing time and work.

In the case of a business that have to cut a great quantity of food every day, we suggest an automatic commercial slicer, designed to operate automatically without any human intervention.

4.Choose a model that can be disassembled

In the choice of your commercial slicer, we suggest to choose a model that can be disassembled, in which any single part can be dismantled in order to be checked and cleaned when necessary. A periodic check – and, in particular, the cleaning – is indeed an extremely important process to maximize the duration and the efficiency of any slicer: rust and corrosion are always behind the corner, responsible of compromising the hygiene and the correct operation of the slicer.

5.Compliance with the current European regulation

Hygiene and safety of the cutting process are two essential qualities that should never been underestimated when choosing a commercial slicer. For this reason, it is always better to choose a slicer complaining with severe regulations, granting the machine under many points of view:

- Electric compatibility,

- Hygiene,

- Use of non-toxic or dangerous materials,

- Safety of the cut mechanism.

The most serious producers make available only compliant slicers, for a machine that focus on the health and safety of the worker and the customer who eat the final product.

Customize your commercial slicer

Sometimes a slicer is not just a machine to cut and slice food: it often is a furnishing element, placed in plain sight before the customers’ eyes. To add value to your store or supermarket you can customize your slicer with a wide range of colors, choosing a slicer with customized knobs or a painted machine.

The first choice is the easiest and the most economic: we just replace standard knobs and other plastic parts with colored components of your choice. On the other hand, choosing a painted slicer is more expensive, but the results are impressive: the machine is coated on its metallic parts with a layer of moist and corrosion-resistant paint, which creates a beautiful effect.